Big Data EVT

“8 oz” you said. This dang bar, man.

Battlebots in the Cloud §

To celebrate moving to the Bay Area, and by “celebrate” I mean “forgot that I registered for a robot combat event in a farm show complex in Harrisburg back when I was still living on the East Coast and now have to beast one so I can fly it into aforementioned Pennsylvanian snow pile,” I started living in the Google Workshops around January with a 12.4 oz chunk of hardened steel, a feverishly drafted new design, and dreams of brushless synergy.

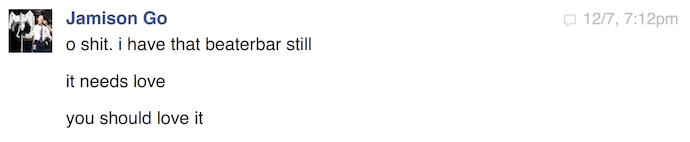

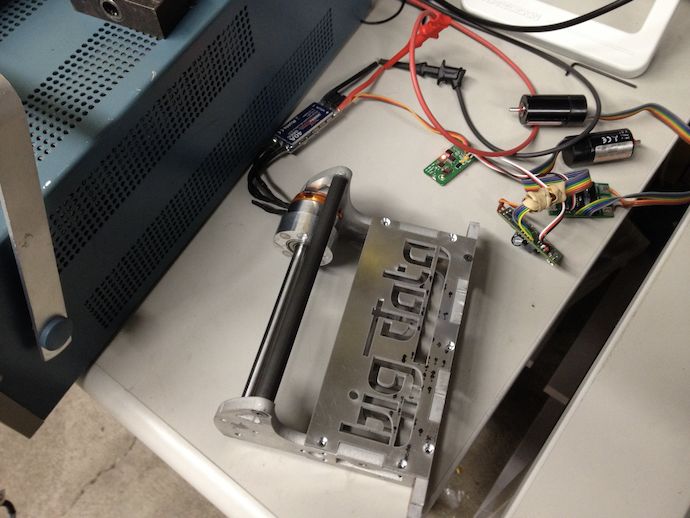

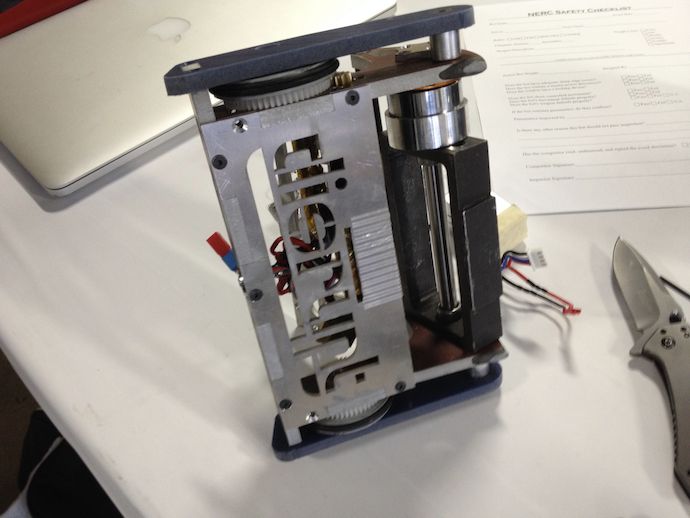

The concept for my “new*” beetleweight (3 lb) Big Data is simple: a “high” voltage† sensored brushless drivetrain coupled to the beater bar from Cake ReMix. With a vertically-hitting weapon like the bar, the robot has to hit the wall in order to right itself to the correct orientation.

This means that the robot needs be able to drive upside-down. The drivetrain was designed around ridiculous sensored inrunners.

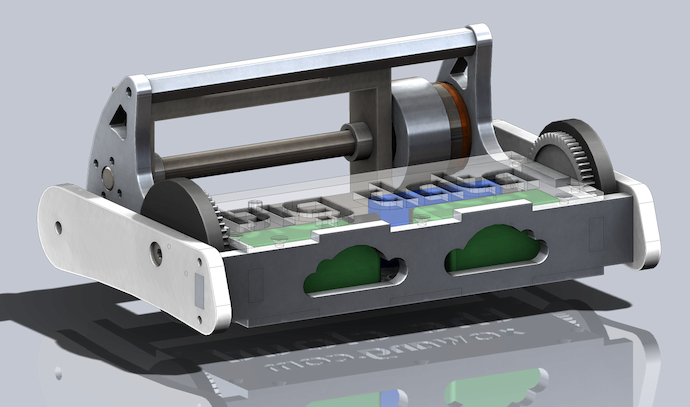

These Maxon EC 22 200118 motors are tuned for mo’ torque. They’re filled inside with globs of hundreds of turns of magnet wire thinner than hair to create a 400 RPM/V motor that’s only 22 mm in diameter. To give you an idea of how “cool” these are wound, they have 11.7 Ohms of phase-to-phase resistance.

The first order of business is to take the gearhead off, since it was so well jammed on the motor that I couldn’t get it off even with a heat gun and much vice gripping.

The connectors are huge!

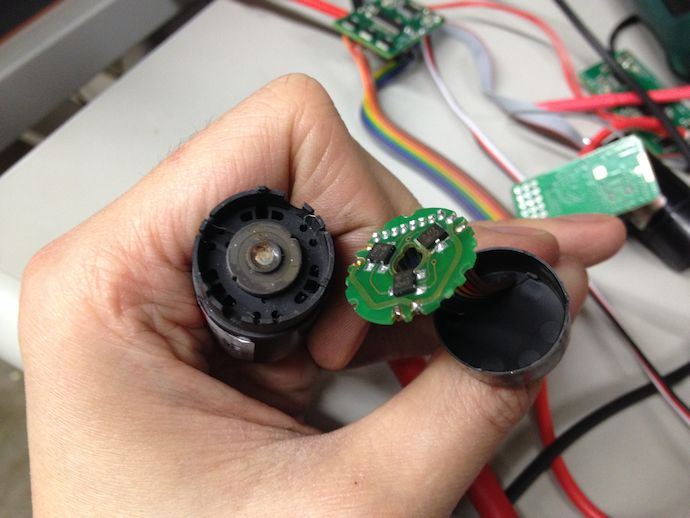

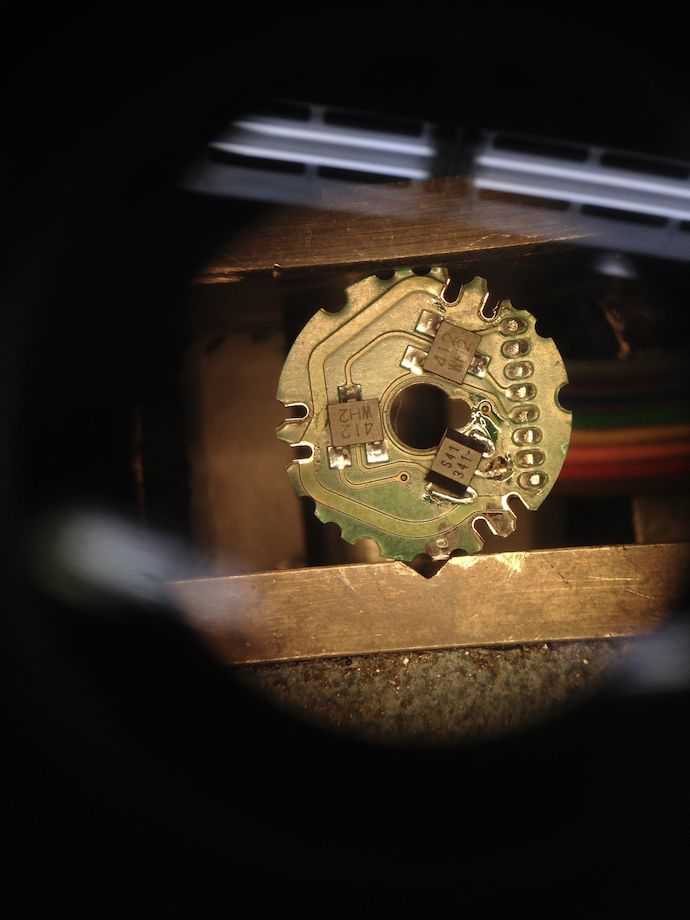

These were well used bargains from eBay. On one motor, a hall sensor which detects the rotor position was stuck at zero volts all the time. The motor had some visible rust on it, so I pulled it apart to have a look at the damage.

@#$%.

Pulling off the ass of the motor had the exact same tugging and twanging as plucking three pairs of hairs out of your head. The hall sensor board also terminates the six leads out of the windings‡, and I had pulled it clean off.

Also that round magnet, shaft, and a sensor all definitely have rust on them. Time for some shady repairs.

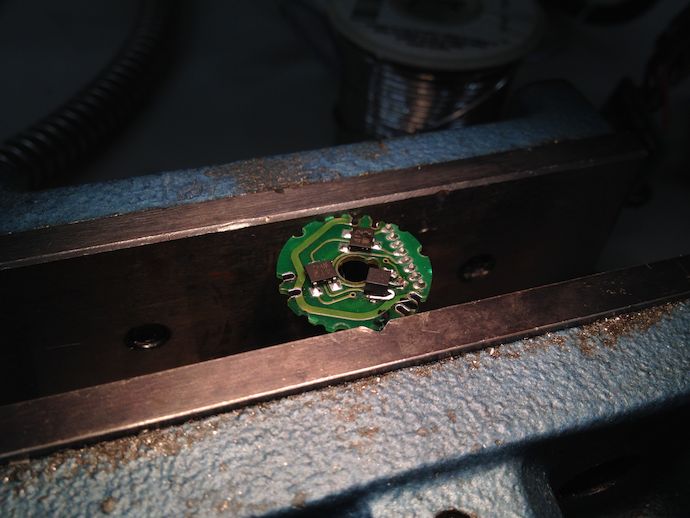

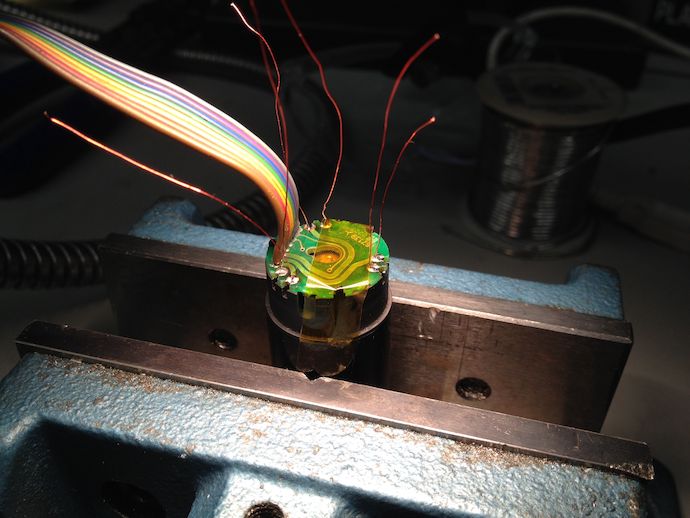

With tweezers I tied more magnet wire onto the remaining stubs and soldered them in place. Pencil eraser for scale.

As for the dead sensor… well, let’s see if you can figure out what I did.

I may or may not have tried to sand down the new sensor to make it thinner and had to repeat this whole repair because electronics don’t work like that. >.>

Done!

Also I took a trip to Squaw Valley woooo Northern California.

Wire it up and it runs. Ship it!

Oh and what are they connected to, you ask?

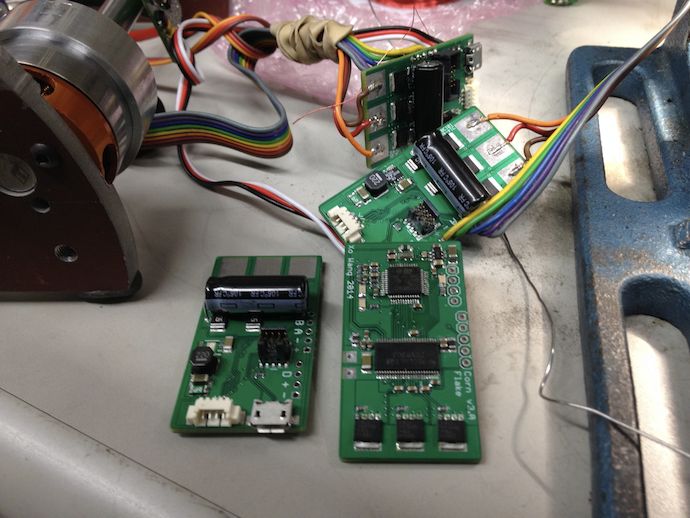

These are Cornflakes, version 3.0 of the beloved Corntroller series. Same good ol’ ingredients, new packaging.

The motor bell is a new design. The face of the bell has magnets pressed in that grip the steel weapon bar and transmit torque through friction. This allows slip when the bar is hit, reducing damage to the motor in the worst case, or preventing sensorless driver desync in the best case.

The motor can is literally glued in with “green sauce,” or Loctite press fit retaining compound. It’s anaerobic methyl acrylate adhesive that activates in the absence of air in tight spaces. There’s also a less viscous version of green sauce that can wick into slip fits through capillary action.

The whole thing was designed in a week and built in a week. It was seriously tremendously rushed job, with most of the design work put towards reducing manual tasks (more waterjet!) and cutting many corners (inaccurate mass modeling, missing holes and fasteners).

I usually spend months designing and committing thoughts to paper notes, before transferring to SolidWorks features over a week or two. But in this case, the whole process was compressed down to a week. I had doubts about it before even sending off the waterjet files.

Anyways, ship it (to Harrisburg)!

Everything about this robot sucks §

Seriously. Even when not damaged, the weight distribution is so far forward that Big Data could use hardly any of its beefy drive, the HobbyKing 6S controller could sync only to the weapon motor once every ten tries, and even when it did the magnetic clutch didn’t grip the beater bar tightly enough to spin it well.

The real clincher was how fragile everything was. The drive motors were only face mounted with three M2 screws each to a frame rail, so after the first hit the mount points stripped out and both motors were hanging out in free space.

Using a 5-face box made of 1/4 in 7075 was also a bad idea, as was putting the weapon between two unsupported rails that easily snapped off. Various screws were loaded in shear. Heck, even the drive gears didn’t mesh that well. Everything that could be crappy about an honest attempt at a non-ass bot, I made crappy.

But the Cornflakes held up fine, so I taped the drive motors back in, fixed the weight distribution by removing the beater bar, and tossed it once more unto the breach.

This is one cloud technology that failed to disrupt.

On the other hand, Sheboygan.